What is pharmaceutical manufacturing process

What is the pharmaceutical manufacturing process?

Whenever any medicine is manufactured, first of all formulation, staging and weight, mixing and granulation, drying, compression, coating, packing, and labelling are all processes of medicine manufacturing.

Process name

- Formulation

- Staging and weighting

- Mixing and granulation

- Drying

- Coating

- Quality control

- Packing and Labelling

- Distribution

1. Formulation

Formulating is a multistep process in which active and non-active ingredients make tablets, capsules, and creams. The formulation ensures that the medicine is stable and properly absorbed into the body

2. Staging and weighting

Staging and weighing are essential in the production of pharmaceutical medicines because the right drug is required to get the right amount of ingredients, and the raw materials are checked and weighed. After this process, the ingredients are kept in clean containers..

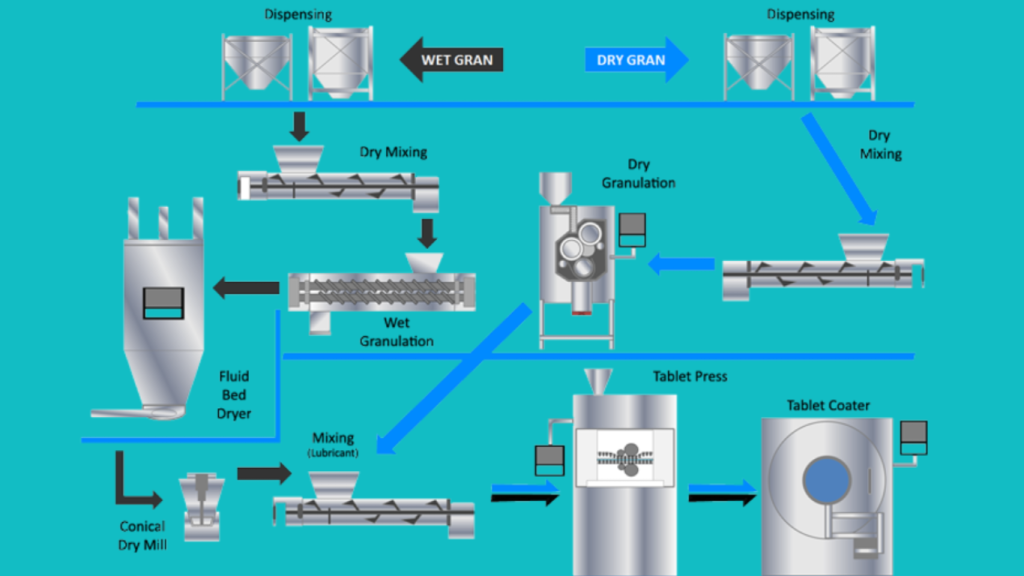

3. Mixing and Granulations

Mixing and granulations are essential processes in the pharmaceutical industry for creating uniform granules and homogenous blends in powder, which is used directly to make tablets and capsules. It is mixed and granulated in different ways, like rapid mixer granulate, high-shear mixer, melt granulate, and direct compression.

4.Drying

Drying is a common unit operation used to reduce the level of water or organic solvent in pharmaceutical material to acceptable Drying is a dangerous method in the pharmaceutical industry that removes moisture and helps stabilise and maintain the drugs. Some of its common methods are as follows:

1)Tray dryer 2) Fluidised bed dryer 3) Spray drying 4) Freeze drying

5. Coating

Pharmaceutical coating, or what we call it, is used on the outside of tablets, capsules, and granules to give them a dosage form, improve the taste, protect the environment, beautify the product, etc. In this method, the coating film is produced by melting and spraying the coating material onto the surfaces of the treated components via electricity. The technique can be applied to a large variety of materials

6.Quality Control

Quality control in the pharmaceutical industry is a dangerous process because, after quality control maintenance and safety, the products reach the consumers. QC ensures that the final product reaches consumers and meets the highest quality standards. Ways to maintain quality in the pharma industry are as follows:

- Raw material testing

- In process control

- Finished product testing

- Good Manufacturer Practice Compliance

- Documentation and record-keeping

- Validation and qualification

- Microbial testing

- Packing and labelling control

- Environment monitoring

- Batch release and market surveillance

7. Packing and labelling

Packing and labelling are required to properly maintain the medicine. It is very important in the pharmaceutical industry as it prevents the products from getting damaged. Drug labelling, also referred to as prescription labelling, is a written, printed, or graphic matter. upon any drug or any of its containers, or accompanying such a drug. Drug labels seek to identify drug contents and to state specific instructions or warnings for administration, storage, and disposal. The methods of packing and labelling are as follows:

1} Primary packing and labelling

2) secondary packing and labelling

3) tertiary packing and labelling

8. Distribution

Distribution plays the most important role in the pharmaceutical industry. When the medicine is ready, it goes from the company to the distributor, then to the wholesaler, and then to the retailer. There are many ways of distribution, such as the following:

- Manufacturer

- Wholesale Distributors

- Pharmacies and hospitals

- Digital Transformation

Conclusion: